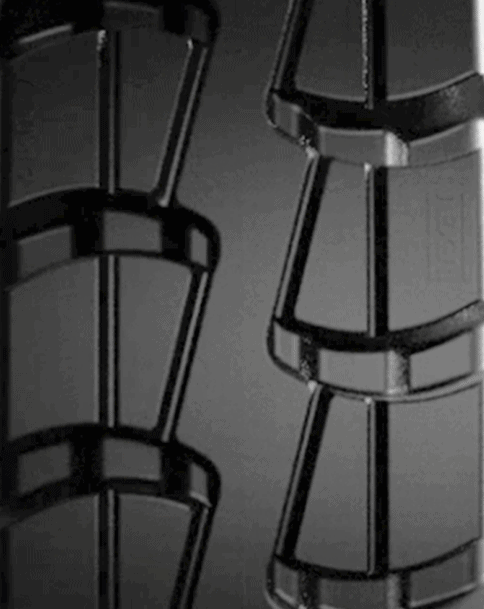

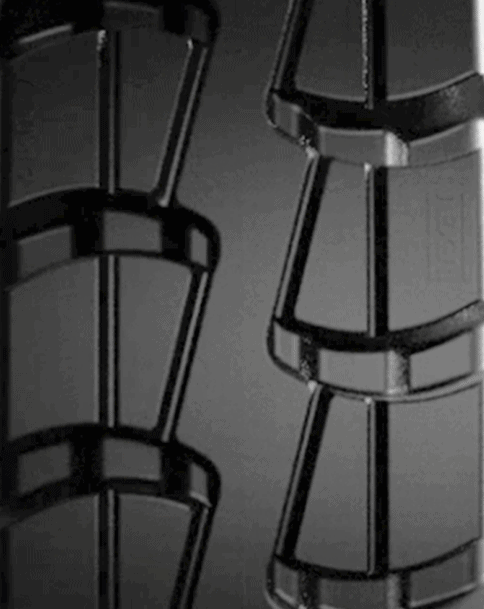

Tread:

‹ Back to Solid Pneumatic Forklift Tires

Westlake SR61 Solid Pneumatic Forklift Tires

Anti-Arc sidewall design, low rolling resistance tread compound, low heating central compound and unique base compound all enables great endurance.

More powerful performance and stability. Deeper and optimized volume of tread part makes efficient management of the vehicle giving longer service life. 3-stage construction.

Available tread patterns:

- SR 61

- SR 61 Non-Marking

Overview

Performance Defined

- Smooth Driving & Cooler Running Multi tread design enables better traction and stability. 3-stage compound delivering a smooth ride for comfort. After 2 hours runtime at a full load, the SR61 was 100°F cooler than the leading Solid Shaped Pneumatic tested.

- Premium Sidewall Tread Compound Delivers cut and wear resistance. Generates less heat in operation. This gives a longer life expectancy and low rolling resistance. The SR61 tread compound experienced a 31% less wear in a wear test over a leading competitor tire.

- Improved Traction & Tread Directional tread design reduces lateral slip and enables stability. The SR61 tread compound is 26% stronger in a tear test than the GS Solid Shaped Pneumatic. Tear test results correlate with abrastion, cut and chip resistance.

- Tread Compound Synthetic blend low rolling resistance compound enables exceptional tire stability

- Sidewall Compound Delivers cut and wear resistance. Generates less heat in operation giving longer life expectancy.

- Center Compound Soft cushion compound for a more comfortable ride and heat built-up characteristics.

- Base Compound Unique base compound with embedded high strength steel bead wires for exceptional performance.

- Stranded Bead Wires Embedded into the base compound are high strength steel bead wires enable the fiex tire stability on the wheels without slippages.

Available Sizes

- 500 x 8

- 18 x 7

- 600 x 9

- 650 x 10

- 700 x 12

- 825 x 15

- 28 x 9

- 300 x 15

- 1400 x 24

- 1400 x 25

Contact a Sales Associate or Call (203) 239-4141